Aluminum rectangle bar – Manufacturer & Supplier in Iran – Export from Our Factory

Aluminum rectangle bar are among the most widely used semi-finished aluminum products due to their strength, machinability, corrosion resistance and excellent weight-to-strength ratio. As a leading manufacturer and supplier in Iran, alummetal factory delivers high-quality aluminum rectangular bars for domestic industries as well as global export markets.

With advanced production lines, strict quality control, and access to premium raw materials, we supply customers with reliable products suitable for engineering, construction, transportation, machinery manufacturing and industrial applications.

What Is an Aluminum Rectangle Bar?

An aluminum rectangle bar is a solid, flat-sided bar with a rectangular cross-section, produced through extrusion or rolling processes. It is commonly used when high strength, low weight, and easy fabrication are required.

Depending on customer needs, aluminum rectangle bars can be produced in various widths, thicknesses, lengths, alloys and temper grades.

Common Alloys Used

2024 Aluminum Alloy

2024 aluminum is one of the strongest alloys in the 2xxx series due to its high copper content. It is well known for its excellent fatigue resistance, which makes it a preferred alloy for aerospace components and high-performance mechanical parts. The alloy offers a very high strength-to-weight ratio, making it a perfect replacement for steel in applications where weight reduction is critical.

Another important characteristic of 2024 aluminum is its outstanding machinability. It can be easily milled, drilled, and formed into complex shapes. However, compared to other alloys, its corrosion resistance is lower, especially in moist or marine environments. For this reason, 2024 aluminum is often used with protective coatings, cladding, or anodizing when exposed to harsh conditions.

In flat bar form, 2024 aluminum provides excellent rigidity and dimensional stability. This makes it ideal for aircraft fittings, structural frames, fasteners, and precision machined components where both strength and fatigue performance are essential.

5083 Aluminum Alloy

5083 aluminum is the strongest non-heat-treatable alloy in the 5xxx series, known for its exceptional corrosion resistance, especially in marine environments. The presence of magnesium as the primary alloying element gives it outstanding resistance against seawater, chemicals, and industrial atmospheres. This is why 5083 aluminum is widely used in shipbuilding, offshore platforms, and watercraft structures.

In addition to corrosion resistance, 5083 aluminum offers excellent weldability. Welding does not significantly reduce its strength, making it suitable for applications requiring large welded structures. Its mechanical properties remain stable even at cryogenic temperatures, which is an important advantage for LNG tanks and cold storage equipment.

As a flat bar, 5083 aluminum performs exceptionally well in load-bearing, structural, and corrosive environments. It is commonly used for marine frames, pressure vessels, vehicle armor, and transportation equipment where durability and resistance to harsh conditions are essential.

6061 Aluminum Alloy

6061 aluminum is the most versatile and widely used alloy in the 6xxx series due to its balanced combination of strength, corrosion resistance, weldability, and machinability. It is a heat-treatable alloy that achieves excellent mechanical performance in the T6 temper, making it suitable for a wide range of structural and engineering components.

One of the most significant advantages of 6061 aluminum is its weldability. Welding does not severely compromise its properties, unlike many high-strength alloys. Its corrosion resistance is also impressive, allowing it to perform well outdoors, in industrial environments, and in transportation applications. Its machinability is excellent, making it a popular choice for precise and detailed machining processes.

In flat bar form, 6061 aluminum is used in construction, machinery, vehicle frames, industrial components, and general-purpose structures. Its combination of mechanical strength, weight savings, and cost-effectiveness makes it one of the most common alloys for aluminum bars and extrusions.

7075 Aluminum Alloy

7075 aluminum is one of the highest-strength aluminum alloys available, comparable to many steels but significantly lighter in weight. This alloy is dominated by zinc as its primary alloying element, resulting in exceptional tensile strength, fatigue strength, and toughness. It is widely used in aerospace, defense, motorsports, and applications where maximum performance is required.

Despite its remarkable strength, 7075 aluminum has lower corrosion resistance than alloys such as 5083 or 6061. However, with anodizing or protective coatings, it can perform well even in demanding environments. It is also less weldable than other alloys, making it more suitable for machined parts rather than welded structures.

7075 aluminum flat bars are commonly used in aircraft components, high-performance gears, drive shafts, tooling, and precision mechanical parts. They are ideal for applications where every gram of weight matters while maintaining maximum structural integrity.

Comparison of 2024, 5083, 6061, and 7075 Aluminum Alloys

Below is a clear comparison of the four major alloys:

Strength

-

Highest Strength: 7075

-

High Strength: 2024

-

Medium Strength: 6061

-

Medium–High (Non-Heat-Treatable) Strength: 5083

Corrosion Resistance

-

Excellent (Best): 5083

-

Very Good: 6061

-

Moderate: 2024

-

Moderate: 7075

Weldability

-

Excellent: 5083, 6061

-

Good: 1100 / 1050 (for reference)

-

Poor: 2024, 7075

Machinability

-

Excellent: 2024, 6061, 7075

-

Good: 5083

Best Applications

-

2024: Aerospace, mechanical parts, high fatigue applications

-

5083: Marine, shipbuilding, chemical environments, welded structures

-

6061: Construction, machinery, automotive, general engineering

-

7075: Aerospace, defense, motorsport, high-load precision parts

Cost

-

Highest Price: 7075

-

High Price: 2024

-

Mid Price: 5083

-

Best Value: 6061

Aluminum Alloy Comparison Table (2024 – 5083 – 6061 – 7075)

| Property / Feature | 2024 Aluminum | 5083 Aluminum | 6061 Aluminum | 7075 Aluminum |

|---|---|---|---|---|

| Series | 2xxx (Al-Cu) | 5xxx (Al-Mg) | 6xxx (Al-Mg-Si) | 7xxx (Al-Zn) |

| Strength Level | High | Medium–High (non-heat-treatable) | Medium | Very High |

| Tensile Strength (Typical) | Very High | High | Medium | Extremely High |

| Fatigue Resistance | Excellent | Good | Good | Excellent |

| Corrosion Resistance | Moderate | Excellent (Best) | Very Good | Moderate |

| Weldability | Poor | Excellent | Excellent | Poor |

| Machinability | Excellent | Good | Excellent | Excellent |

| Heat Treatable | Yes | No | Yes | Yes |

| Common Tempers | T3, T4, T6 | O, H111, H116 | T4, T6, T651 | T6, T651 |

| Main Alloying Element | Copper | Magnesium | Magnesium + Silicon | Zinc |

| Workability / Formability | Moderate | Good | Good | Moderate |

| Weight-to-Strength Ratio | Very Good | Good | Good | Excellent |

| Typical Applications | Aerospace, fasteners, high-stress and fatigue parts | Marine, shipbuilding, cryogenic tanks, welded structures | Construction, machinery, automotive, general engineering | Aerospace, defense, motorsport, high-performance precision parts |

| Relative Cost | High | Medium | Low–Medium | Highest |

Advantages of Aluminum rectangle bar

1. Lightweight but Strong

Aluminum is one-third the weight of steel while offering impressive mechanical strength, making it ideal for parts where weight reduction is important.

2. Excellent Machinability

Aluminum rectangular bars can be easily cut, drilled, welded and shaped, supporting various fabrication processes.

3. Corrosion Resistance

Natural oxide layer protects aluminum against moisture, chemicals, and atmospheric corrosion. Additional surface treatments enhance durability.

4. High Thermal and Electrical Conductivity

Suitable for heat exchangers, busbars, cooling systems, and energy applications.

5. Cost-Effective

Competitive raw material pricing and efficient extrusion technology in Iran provide cost advantages in both domestic and export markets.

Our Aluminum rectangle bar Production in Iran

Our factory uses modern extrusion presses, homogenizing furnaces, heat-treatment lines, and precision cutting systems. The production process includes:

-

Billet casting with quality-controlled chemical composition

-

Homogenization to ensure mechanical consistency

-

Extrusion through precision dies

-

Straightening and stress-relief processing

-

Heat treatment (T4, T5, T6) depending on alloy

-

Dimension control and surface inspection

-

Cut-to-length machining and packaging for shipment

Every batch is tested for tensile strength, hardness, dimensional accuracy and surface quality.

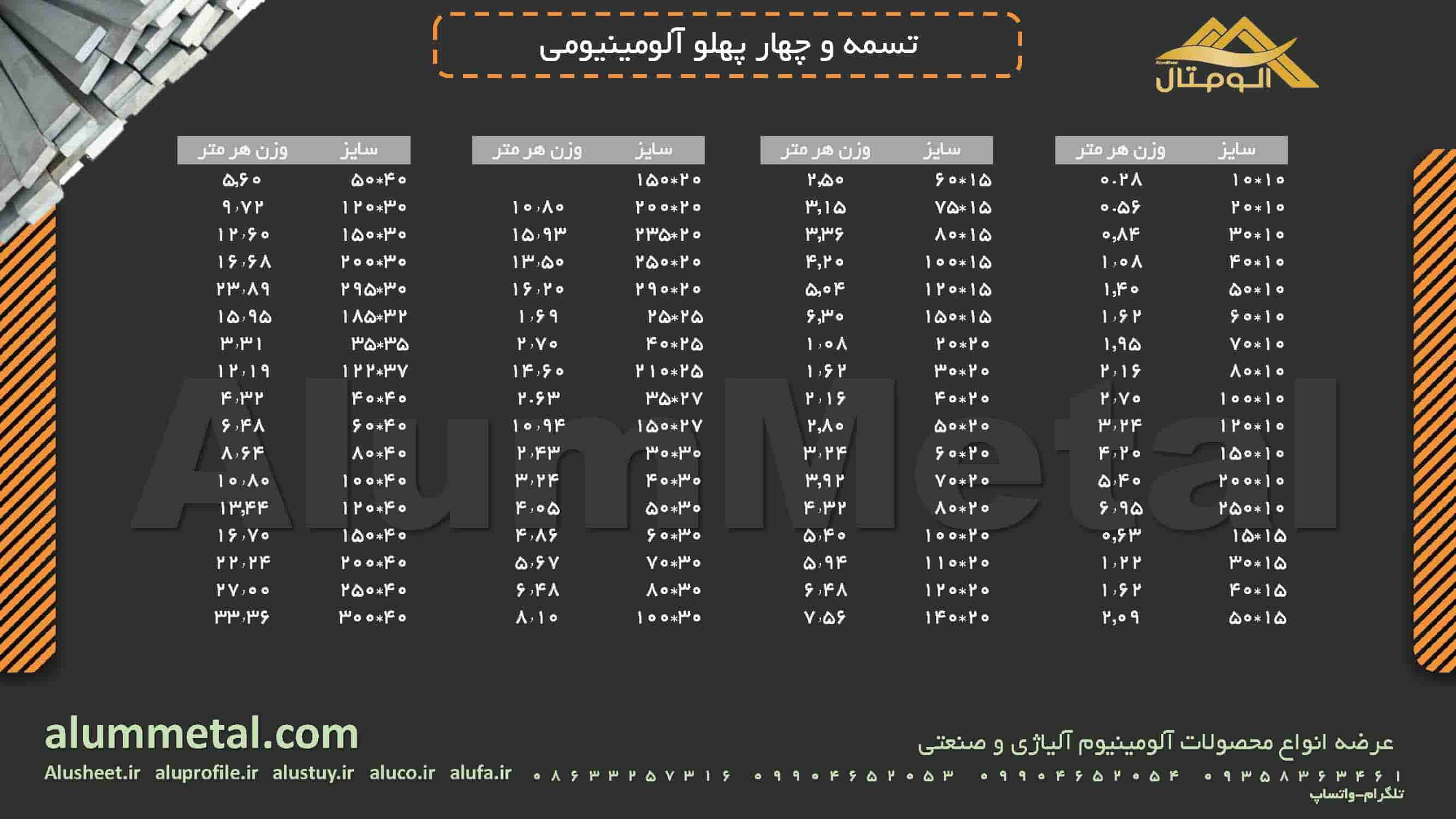

Sizes and Customization Options

We supply both standard sizes and custom dimensions based on technical drawings.

Available Dimensions

-

Width: 10 mm to 300 mm

-

Thickness: 3 mm to 100 mm

-

Length: 3 m, 6 m or customized

-

Tolerance: ISO and EN standards

-

Surface: mill finish, anodized, brushed, powder-coated

-

Temper: O, T4, T5, T6, T651

-

Packaging: export-grade bundles, wooden pallets, shrink wrap

Custom extrusion is available for bulk orders.

Aluminum Strap Catalog

Applications of Aluminum rectangle bar

Due to their versatility, aluminum rectangular bars are used in many industries:

Construction & Architecture

-

Frames, supports and reinforcements

-

Stair structures and rail systems

-

Architectural trims and decorative components

Machinery & Industrial Equipment

-

Machine bases and brackets

-

Conveyor structures and fixtures

-

Hydraulic and pneumatic systems

Transportation

-

Automotive parts

-

Trailer frames

-

Bus and truck body components

Electrical & Thermal Applications

-

Busbars

-

Heat sinks and radiator components

General Fabrication

-

Furniture

-

Tools and fixtures

-

Custom engineering products

Why Choose Our Factory in Iran?

1. High-Quality Manufacturing Standards

We follow EN, ASTM and ISO quality standards to ensure consistent mechanical and dimensional properties.

2. Competitive Pricing

Iran’s cost-effective production environment allows us to supply at lower prices without compromising quality.

3. Fast Delivery and Export Capability

Our factory exports aluminum rectangle bars to multiple countries in Asia, Europe, Africa and the Middle East.

We provide:

-

Custom export packaging

-

Certificate of Origin (COO)

-

Material Test Reports (MTR)

-

SGS/Third-party inspection upon request

4. Technical Support

Our engineering team assists customers with alloy selection, design recommendations and machining guidance.

5. Large Production Capacity

High-volume orders and continuous supply are available due to our advanced extrusion lines and large warehouse inventory.

Export Services from Iran

Our export department manages full logistics including:

-

International shipping (sea, land, air)

-

Customs clearance

-

Container loading supervision

-

Palletized and moisture-proof packaging

We regularly export aluminum rectangle bars to Turkey, UAE, Oman, Iraq, India, Russia and European markets.

How to Order Aluminum rectangle bar

Customers can request:

-

Detailed price list

-

Alloy comparison

-

Technical data sheet

-

Custom extrusion quotes

-

Sampling for long-term supply contracts

We supply both small quantities and bulk industrial orders.

دیدگاه خود را ثبت کنید

تمایل دارید در گفتگوها شرکت کنید؟در گفتگو ها شرکت کنید.